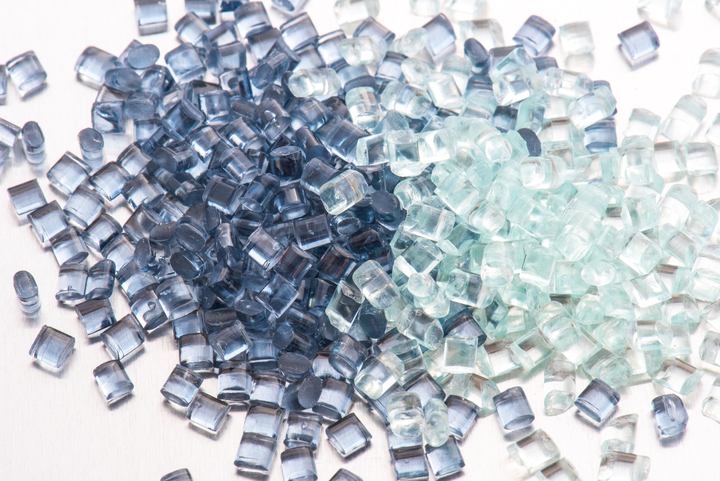

Description

High-density polyethylene (HDPE) is a thermoplastic polymer made from petroleum. HDPE is one of the most versatile plastics. It is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards and piping. Known for its exceptional tensile strength and high strength-to-density ratio, HDPE plastic has high impact resistance and a high melting point.

Properties and features

Applications

Packaging

Bottles and flasks, rigid containers (cans and drums for storing chemicals, oils and other liquids), bags and packaging film (plastic bags, stretch film and food bags).

Toys

Outdoor toys (slides, swings) and children’s toys.

Hoses, caps

Hoses (irrigation systems, drinking water pipes, ect) and caps (for water bottles, chemical cans and food containers).

Films

Tarpaulins, damp-proof construction film, packaging film for industrial and consumer products.

Cosmetic bottles

Shampoo and lotion bottles and cream and gel bottles.