Description

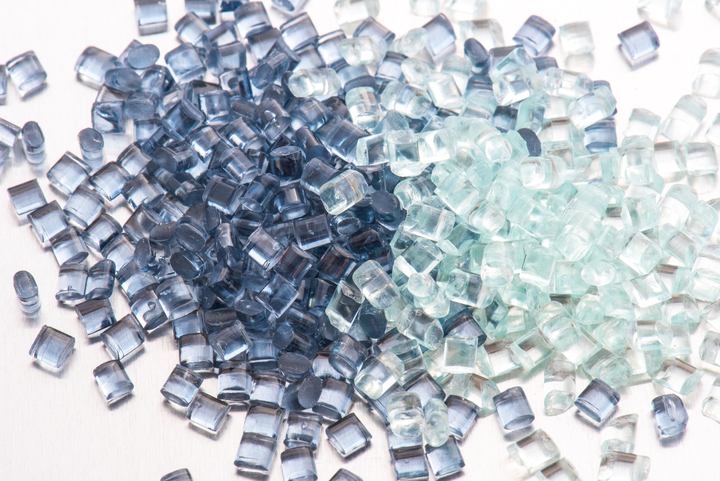

Polyethylene terephthalate (PET) is a semi-crystalline thermoplastic material. PET resin is formed via a polycondensation reaction using purified terephthalic acid (PTA) and monoethylene glycol (MEG) as the feedstock monomers.

Properties and features

Applications

Edible oils, milk and diary products, sauces, condiments…

Carbonated-soft drinks, water, sports drinks, juices, ready-todrink tea and coffee, Edible oils, milk and diary products, sauces, condiments…

Home & Personal care

Cleaning and laundry products, detergents, hand sanitizer, and other hygiene products ; Shampoo, soaps, facial cleanser, body wash, lotions, perfumes and cosmetics

Thermoform containers

Deli-containers, fresh produce trays, microwave and ovenable meal packaging, …

Pharma packaging

Blister packs, vials, bottles, and other containers