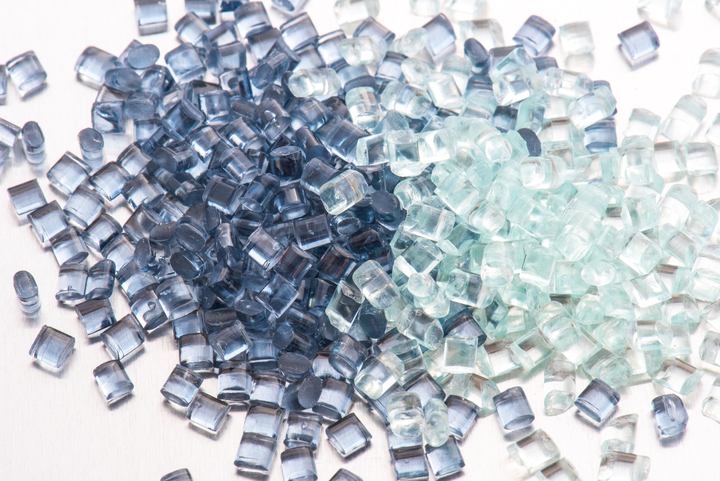

Description

Styrenics, derived from styrene, include polymers such as acrylonitrile-butadiene-styrene (ABS). They are used for their rigidity, lightness and ease of moulding, in applications ranging from food packaging to electronic components and toys.

Properties and features

It produces smooth, glossy finished surfaces, often used for applications requiring good aesthetic appearance.

ABS can be easily coloured, either in the mass before moulding, or afterwards via painting or coating processes, offering great aesthetic flexibility.

Impact resistance: ABS is particularly appreciated for its ability to absorb impact without cracking or breaking, thanks to the butadiene elastomer phase that gives it this robustness.

Rigidity and strength: ABS has good rigidity and resistance to mechanical stress, making products made from it durable and strong.

Excellent fluidity: ABS has good injection-moulding properties and can easily be transformed into complex objects with fine details.

Low processing temperature: It can be moulded at relatively low temperatures compared with other polymers, reducing energy costs and the risk of thermal degradation.

Applications

Industrial applications

Mechanical parts, housings and casings, brackets and fixings

E&E

housings and shells, household appliances, connectors, etc.

Medical

Medical furniture, disposable devices, etc.

Consumer products

Toys, sports equipment, leisure equipment

Automotive

Interior components (dashboards, handles, etc.), exterior bodywork (bumpers, mirror housings, etc.), technical components, etc.